Welcome to the GB Engineering blog! I'm excited to share the journey of how this project came to life.

Where It All Started

It all started when I tried to develop a better remote than the mini remote. I was frustrated with the limitations of existing options—the ergonomics weren't right, the features were lacking, and I knew I could do better. So I decided to build something myself.

My Requirements

| Feature | Mini Remote | GB Remote |

|---|---|---|

| Battery | AA batteries (disposable) | Lithium rechargeable + USB-C |

| Display | No display | TFT color screen with telemetry |

| Connection Status | No indication | Signal quality indicator |

| Battery Level | No indication | Shows both remote & board battery |

| VESC Communication | None - no telemetry | Full VESC telemetry support |

| Throttle Sensor | Potentiometer (wear-prone) | Hall effect sensor (reliable) |

| Haptic Feedback | None | Yes - vibration alerts |

| Wireless Protocol | RF (interference-prone) | BLE (reliable, RF-immune) |

| Safety | ⚠️ Can send full throttle when disconnected | ✓ Safe disconnect handling |

The comparison above shows where we started. The mini remote was functional, but it wasn't designed with the rider truly in mind. I wanted something that felt premium, something that was engineered with purpose.

The Vision

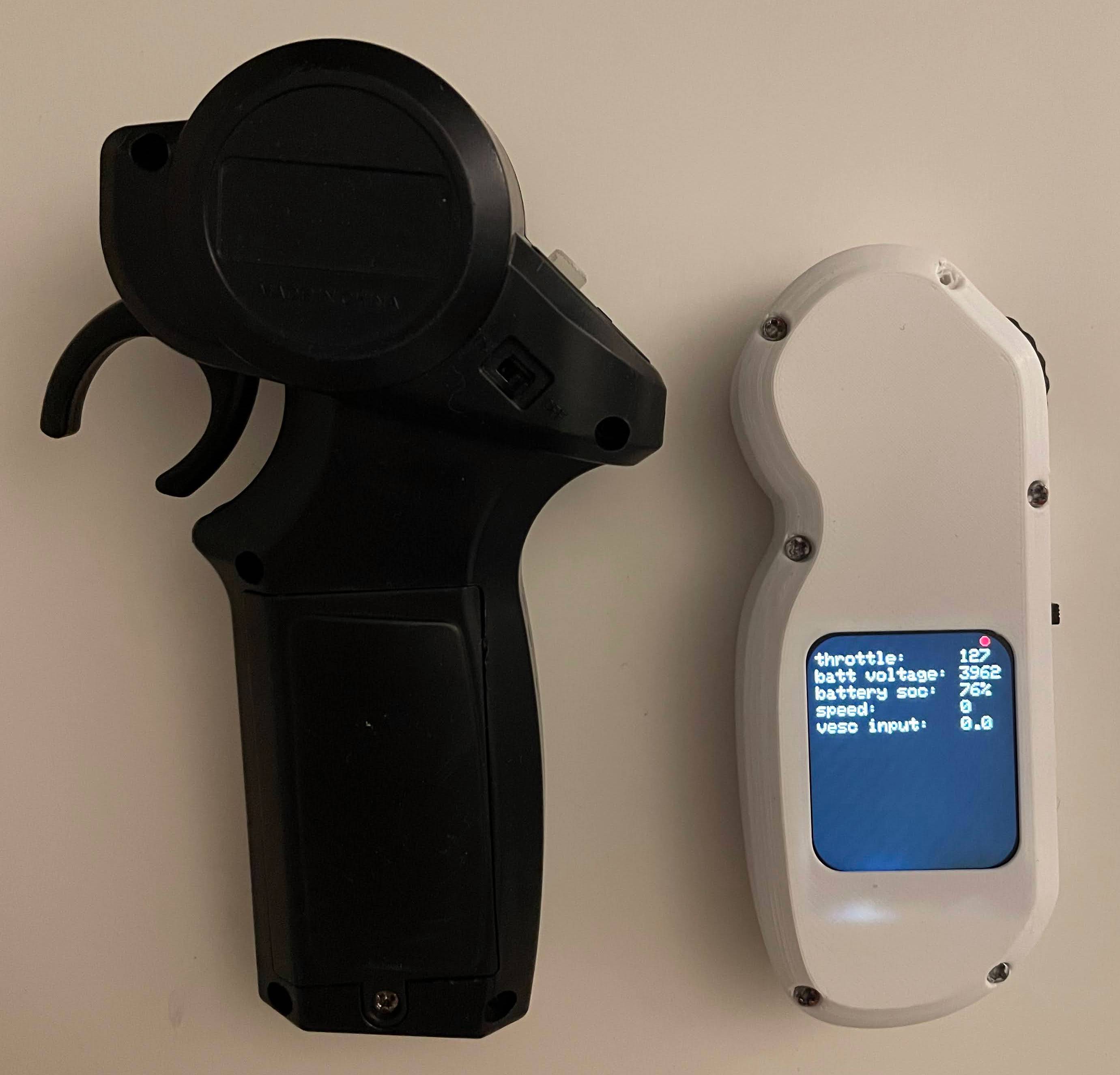

This was the original vision for the product—a clean, ergonomic design that would feel natural in the hand while delivering all the features a serious rider would need.

From this initial concept, the real work began. Turning a vision into reality required countless hours of design, prototyping, testing, and refining.

The Evolution

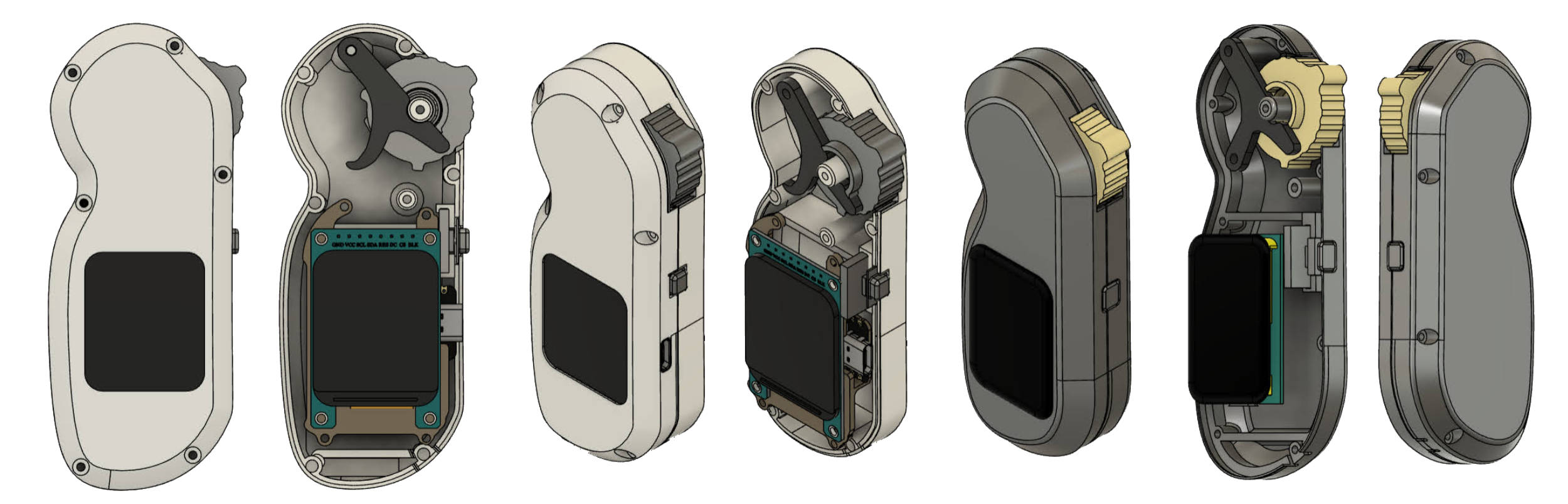

What you see below is the evolution of the GB Remote. Each iteration brought new lessons, new improvements, and new challenges to overcome. From the first rough prototype to the refined product you see today, there were dozens of design iterations to make sure everything worked perfectly.

Every version taught me something new—about ergonomics, about electronics, about what riders actually need. The PCB went through countless revisions. The enclosure was redesigned more times than I can count. But each iteration brought us closer to the goal: a remote that doesn't just work, but works beautifully.

This is just the beginning of our story. Stay tuned for more updates on new features, behind-the-scenes looks at the engineering process, and announcements about upcoming products.